Pharmaceutical / Healthcare

Forefront of current global technical and regulatory advances

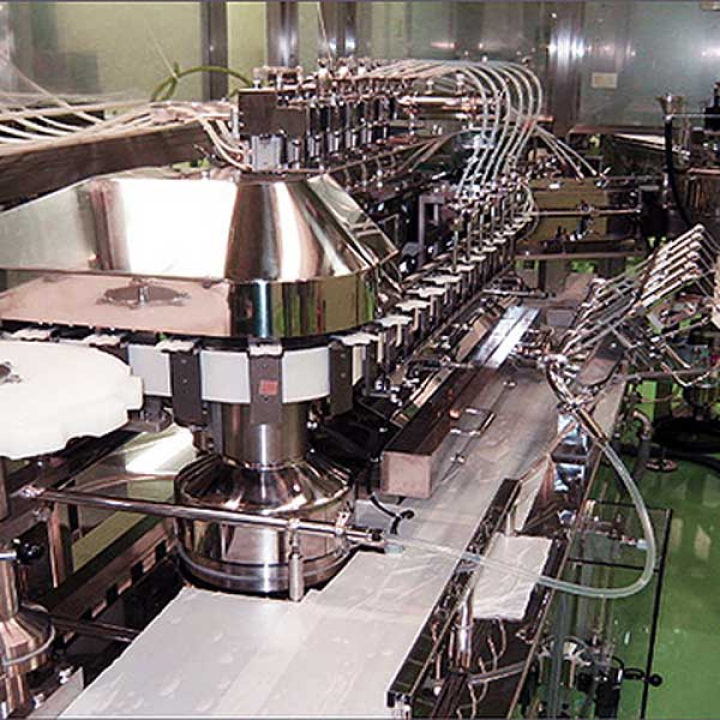

Shibuya Hoppmann provides full service turn-key systems to meet all your pharmaceutical and healthcare production needs. Our GMP compliant range of equipment includes formulation, isolator, decontamination and inspection systems, as well as a variety of pharmaceutical and healthcare packaging systems. From decontamination systems to Aseptic packaging lines, we pride ourselves on our years of experience manufacturing quality pharmaceutical and healthcare equipment. We continue to develop and manufacture innovative equipment that sets the standard in quality, efficiency and contamination control. To date, we have supplied more than 150 integrated pharmaceutical filling and packaging systems worldwide – with a large portion of these being isolator based and designed to maintain high sterility assurance levels.

Contact

Have a question or need additional information?

Careers

Explore our current job openings.