Specialty Feeders and Unscramblers

Standard Products

CapStar Cap Feeder

Product Overview

The CapStar Cap Feeder is designed and engineered to feed and orient flat screw caps, tamper evident caps and other minimal featured products at speeds ranging from 40 to 600 parts per minute. Changeover from one cap to another takes less than five (5) minutes. The cleated elevator belt has a nominal cleat height of 2.00” and a cleat pitch of 4.00” allowing for maximum product loading. It is recommended that the cap diameter not exceed 3.50” with the standard belt, however, other belt sizes are available. Note: Tooling is not included with this unit.

| Part Number | FT301RLASA | |

|---|---|---|

| Motor Style | AC | |

| Motor Voltage | 230/460V | |

| Horsepower | 1/3hp | |

| Total Equipment Weight | 350lbs./159kg | |

| Part Number | FT401RLASA |

|---|---|

| Motor Style | AC |

| Motor Voltage | 230 / 460V |

| Horsepower | 1 / 2hp |

| Total Equipment Weight | 850lbs. / 385kg |

Standard Features

- All stainless steel exterior construction

- FDA approved ABS vacuum formed disc

- Teflon Hardcoat Anodized aluminum bowl

- Polypropylene modular plastic belt

- Manually adjustable discharge height

- FDA approved white urethane cover continuous belt

- No tool changeover

- Small footprint

- Mounted encased controller

- Hopper agitator

- Casters and fixed feet

Available Options

- Polycarbonate covers

- Dual motor drive system

- Washdown motor(s)

- NEMA 1 encased controller

- Elevator extensions

- Continuous welded hopper seams

- Elevator/hopper covers

- Washdown motors

| Product Specifications | ANSI | Metric | |

|---|---|---|---|

| A | Outside Diameter | 40.10″ | 1018.5 mm |

| B | Overall Frame Height | 27.13″ | 689.1 mm |

| C | Bowl Discharge Height * | 17.88″ | 454.2mm |

| D | Bowl Outside Diameter | 36.13″ | 917.7 mm |

| E | Bowl Inside Diameter | 28.80″ | 731.5 mm |

| F | Rim Width | 3.67″ | 93.2 mm |

| G | Bowl Depth | 4.50″ | 114.3 mm |

| H | Level Foot Adjustment * | 2.75″ | 69.9 mm |

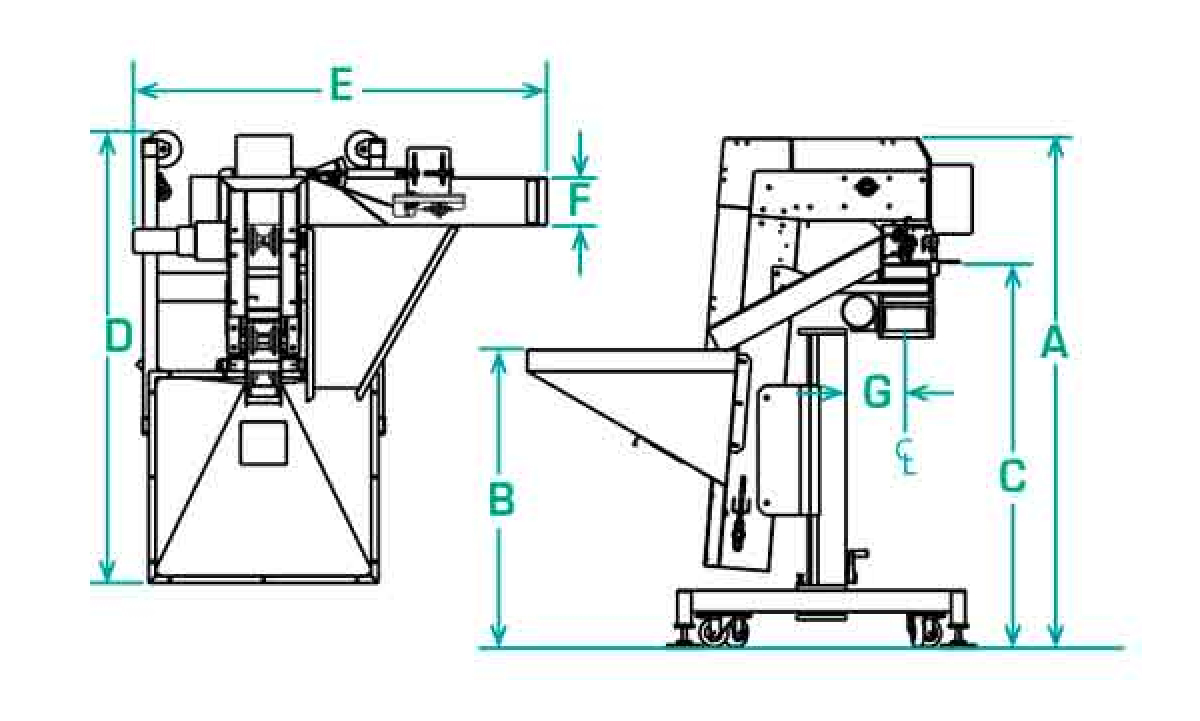

| Product Specifications | ANSI | Metric | |

|---|---|---|---|

| A | Overall Height | 63.13″ – 81.13″ | 1655.0 – 2060.0 mm |

| B | Load Height | 35.75″ – 51.73″ | 908.0 – 1314.0 mm |

| C | Discharge Height | 46.22″ – 62.20″ | 1174.0 – 1580.0 mm |

| D | Overall Length | 60.47″ | 1536.0 mm |

| E | Overall Width | 54.00″ | 1371.0 mm |

| F | Belt Width | 6.00″ | 152.0 mm |

| G | Conveyor Belt Center Line | 7.00″ | 157.5 mm |

The leveling foot has a vertical adjustment of ±1.75”, allowing for a height variation between 1.00” and 4.50”. This may alter the discharge height.

Required Accessories for the FT-15-RD Unscrambler:

- Clockwise Square Tooling Frame and Backup Ring – BUCWFT30SU

- Counterclockwise Square Tooling Frame and Backup Ring – BUCCFT30SU

Shibuya Hoppmann Corporation strives to improve its products and reserves the right to change or discontinue specifications and designs shown in this information sheet without notice and without incurring obligation. Revised: 05/18.